Supply chain expenses are a huge cost to your bottom line, but are rarely captured accurately. Learn how switching to PWL’s Lighter, Safer, Less accident prone offerings can save!

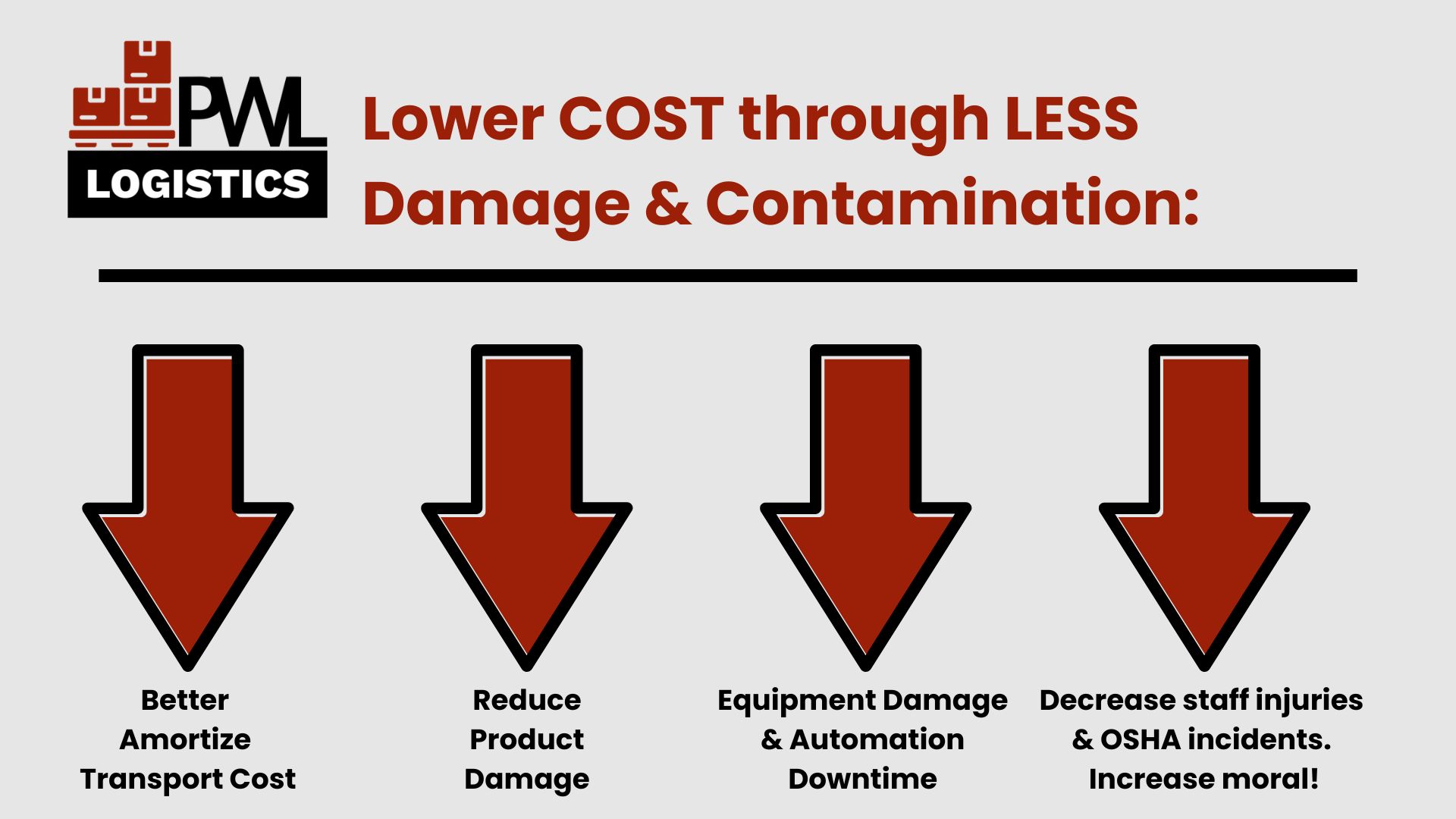

Better Amortize Transport Cost

Weighing 16 pounds, PWL Pallet’s are 75% lighter ( on average ) than the wood pallets they replace. A weight savings of 750 pounds per layer ( based on 2 x 15 cubed pattern ). That works out to 1,500 pounds ( double stacked ) or 2,250 pounds ( triple stacked ) – weight savings per truck! This allows you to package more materials, as a result, better amortize your shipping costs!

Reduce Product Damage

Splinters, Nails and Broken Boards damage packaging and pose hygienic concerns in the process. Wood pallets have big gaps, creating unitization problems, and often require slip sheets. PWL pallets do not need slip sheets ( avg saving ~$1.00 pallet ). PWL pallets Unitize perfectly, no deck board spacing issues.

Equipment Damage & Automation Downtime

Warehousing equipment & Automation is the pillars of modern supply chain. PWL plastic pallets are free of debris that commonly jams our automation. Especially important in ASRS systems, where 100% dimensional-consistency and Zero F.O.D, ensure perfect operational consistency. These factors, along with the lower weight greatly reduce the damage your Automation takes!

Decrease staff injuries & OSHA incidents. Increase moral!

PWL pallets are LIGHTER & Don’t have ANY Nails or Splinters. The designs provide infinite easy hand holds, and ways to grab the pallets. When you do grab them, there are no sharp objects to poke your staff! These pallets ONLY weigh 16 pounds, 75% less than the wood pallets they replace. No splinters/nails to injure staff while handling by hand. Lighter and Safer, better to handle in every way!