In today’s 24/7 world, Automation is often our saving grace. It allows us to multiply our work force, and run our companies through the night. Every industry has turned to Automation. Automation at its highest form, Automated Storage and Retrieval Systems ( ASRS ) are used in the most demanding of operations, allowing large supply chains to remain ahead of their competition. ASRS bring better picking accuracy, greater speed, improved space utilization, and often allow operations to run with minimal input.

Like everything – ASRS are only as strong as their weakest link. What’s the most common missing link in an ASRS? A consistent pallet! ASRS are modern inventions, every part of them exact and consistent every time. The one variable in these systems that is not? The Pallet! Any variable that slows, damages, or confuses the system, costs time and money.

Beyond dimensional issues – wood pallets splinter and drop nails into your automation. If a pallets dimensional issues don’t cause a jam today, the FOD it drops now, can shut you down tomorrow. No Foreign Object Contamination with PWL pallets!

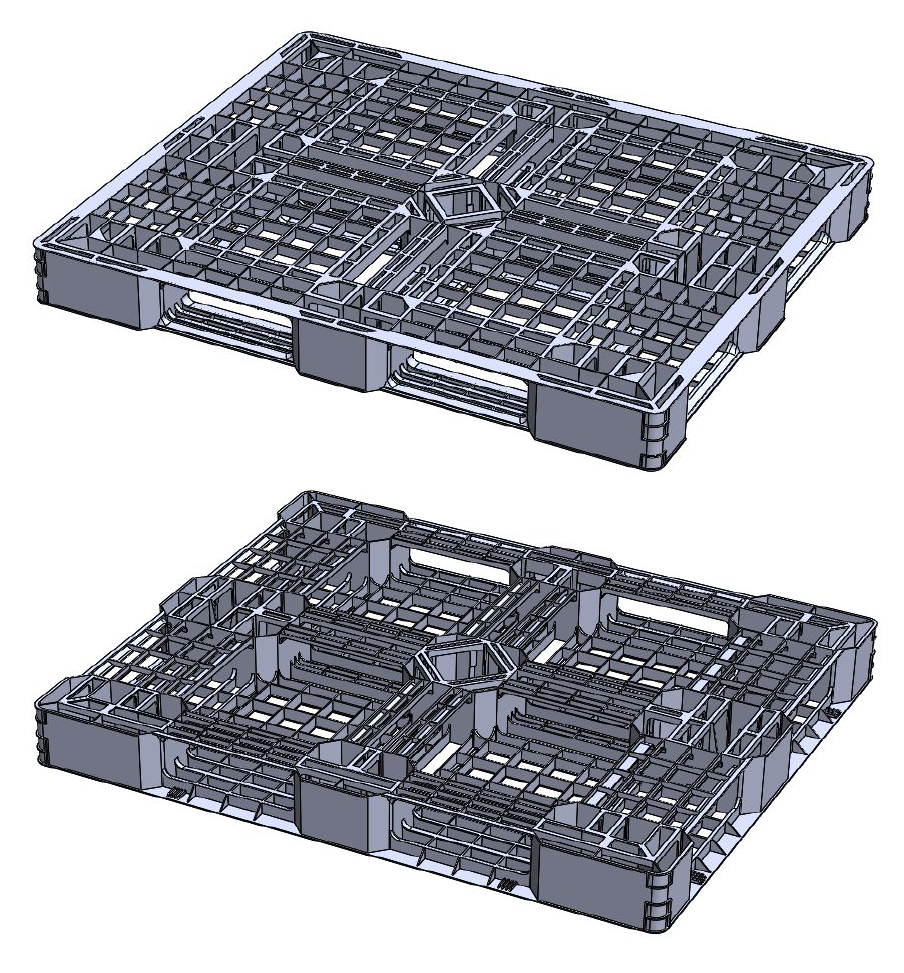

For an exact machine, you need an exact pallet – preferably every time. The PWL line of plastic pallets have exact dimensions, an exact weight, and rugged yet light construction – Every Time! Making PWL Products the Clear Winner for any ASRS application.

Choosing PWL’s plastic pallets reduces interruptions and sets Your Supply Chain up for success.